Rubber HTD Timing Belts

For high-performance industrial drives.

HTD belts provide a high-performance drive system for many industries where durability and low maintenance are required such as textile equipment, processing & packaging, vending machines and conveyor systems.

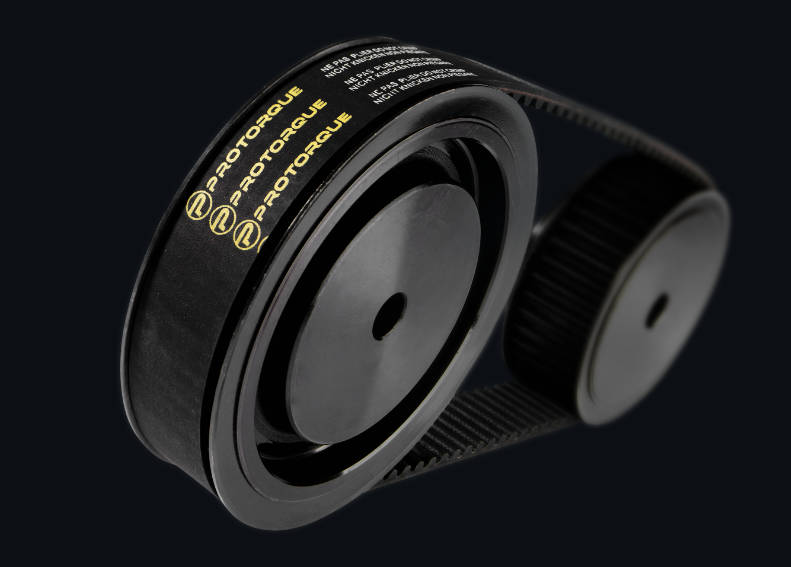

The HTD curvilinear tooth profile improves load distribution and shear resistance, resulting in higher torque and power transmission capabilities.

With a wide speed range and increased load carrying capacity, the HTD belt helps to provide constant driven speeds delivered by a smooth, compact drive design.

These belts offer high operating efficiency with no need for lubrication along with reduced maintenance of constant lengths and belt tensioning.

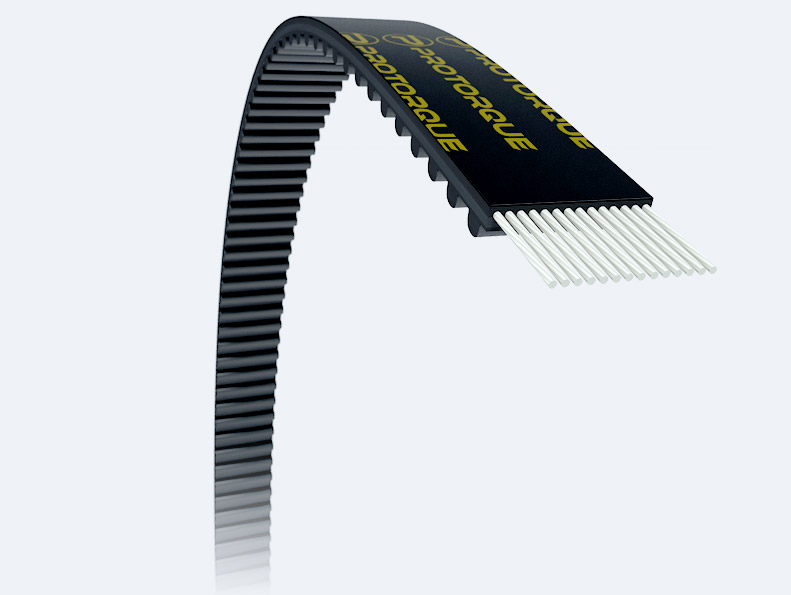

Backing Fabric

Protective and hard-wearing elastomeric rubber backing allows consistent adhesion and minimal frictional wear, permitting reverse idler power transmission.

Tension cords

Strong ‘S and Z’ wound low stretch fibreglass tensile members ensure perfect belt tracking and dimensional stability, as well as excellent flex life and high resistance to elongation.

Tooth profile

Precisely formed HTD tooth profile provides optimal pitching in pulley grooves for extremely accurate operation.

Facing Fabric

Tough, low friction nylon facing provides excellent tooth protection and abrasion resistance.

Temperature

-30°C to +80°C.

Resistant

Moderate resistance to common oils.

Good resistance to heat & cold environments.

Noise

Low noise, high speed ratio, high belt speed.

Standards

Meets RoHS and REACH requirements.

ISO 13050

Technical Information

| ISO 13050 | 5M | 8M | 14M |

|---|---|---|---|

| Properties | |||

| Tensile strength (N/mm) | 160 | 300 | 400 |

| Load (N) | 130 | 240 | 320 |

| Elongation (%) | 4.0 | 4.0 | 4.0 |

| Hardness (Shore A +/- 4°) | 82.0 | 82.0 | 82.0 |

| Adhesion of cloth (N/mm) | 6.0 | 10.0 | 12.0 |

| Adhesion of cord (N) | 400 | 700 | 1200 |

| Tooth shear strength (N/mm) | 50 | 60 | 80 |

| Section Dimensions | |||

| Pitch (mm) | 5.0 | 8.0 | 14.0 |

| Height (mm) | 2.06 | 3.38 | 6.02 |

| Angle (°) | 14 | 14 | 14 |

| Width (mm) | 3.05 | 5.15 | 9.40 |

| Foot radius (mm) | 0.42 | 0.70 | 1.25 |

| Head radius (mm) | 1.49 | 2.46 | 4.50 |

| Belt Thickness (mm) | 3.80 | 6.00 | 10.00 |

| Belt Weight per meter per 10mm width (Kg/m) | 0.041 | 0.063 | 0.108 |

| Min. crimp (mm) | 25 | 40 | 70 |

| Teeth range (min-max) | 45 - 400 | 48 - 450 | 69 - 327 |

| Pitch length | 225 - 2000 | 984 - 3600 | 966 - 4578 |

Product range

Pitches available

Standard widths: 9mm, 15mm and 25mm

| Reference | Size | Length Lp (mm) | No. of Teeth | Tooth Pitch (mm) |

|---|---|---|---|---|

| 225-5M | 5x225Lp | 225 | 45 | 5 |

| 245-5M | 5x245Lp | 245 | 49 | 5 |

| 265-5M | 5x265Lp | 265 | 53 | 5 |

| 285-5M | 5x285Lp | 285 | 57 | 5 |

| 295-5M | 5x295Lp | 295 | 59 | 5 |

| 300-5M | 5x300Lp | 300 | 60 | 5 |

| 305-5M | 5x305Lp | 305 | 61 | 5 |

| 325-5M | 5x325Lp | 325 | 65 | 5 |

| 330-5M | 5x330Lp | 330 | 66 | 5 |

| 350-5M | 5x350Lp | 350 | 70 | 5 |

| 375-5M | 5x375Lp | 375 | 75 | 5 |

| 385-5M | 5x385Lp | 385 | 77 | 5 |

| 400-5M | 5x400Lp | 400 | 80 | 5 |

| 420-5M | 5x420Lp | 420 | 84 | 5 |

| 425-5M | 5x425Lp | 425 | 85 | 5 |

| 450-5M | 5x450Lp | 450 | 90 | 5 |

| 460-5M | 5x460Lp | 460 | 92 | 5 |

| 475-5M | 5x475Lp | 475 | 95 | 5 |

| 500-5M | 5x500Lp | 500 | 100 | 5 |

| 525-5M | 5x525Lp | 525 | 105 | 5 |

| 535-5M | 5x535Lp | 535 | 107 | 5 |

| 540-5M | 5x540Lp | 540 | 108 | 5 |

| 550-5M | 5x550Lp | 550 | 110 | 5 |

| 565-5M | 5x565Lp | 565 | 113 | 5 |

| 575-5M | 5x575Lp | 575 | 115 | 5 |

| 600-5M | 5x600Lp | 600 | 120 | 5 |

| 615-5M | 5x615Lp | 615 | 123 | 5 |

| 635-5M | 5x635Lp | 635 | 127 | 5 |

| 640-5M | 5x640Lp | 640 | 128 | 5 |

| 670-5M | 5x670Lp | 670 | 134 | 5 |

| 700-5M | 5x700Lp | 700 | 140 | 5 |

| 710-5M | 5x710Lp | 710 | 142 | 5 |

| 740-5M | 5x740Lp | 740 | 148 | 5 |

| 750-5M | 5x750Lp | 750 | 150 | 5 |

| 755-5M | 5x755Lp | 755 | 151 | 5 |

| 800-5M | 5x800Lp | 800 | 160 | 5 |

| 850-5M | 5x850Lp | 850 | 170 | 5 |

| 890-5M | 5x890Lp | 890 | 178 | 5 |

| 900-5M | 5x900Lp | 900 | 180 | 5 |

| 950-5M | 5x950Lp | 950 | 190 | 5 |

| 1000-5M | 5x1000Lp | 1000 | 200 | 5 |

| 1050-5M | 5x1050Lp | 1050 | 210 | 5 |

| 1100-5M | 5x1100Lp | 1100 | 220 | 5 |

| 1125-5M | 5x1125Lp | 1125 | 225 | 5 |

| 1200-5M | 5x1200Lp | 1200 | 240 | 5 |

| 1240-5M | 5x1240Lp | 1240 | 248 | 5 |

| 1270-5M | 5x1270Lp | 1270 | 254 | 5 |

| 1420-5M | 5x1420Lp | 1420 | 284 | 5 |

| 1595-5M | 5x1595Lp | 1595 | 319 | 5 |

| 1690-5M | 5x1690Lp | 1690 | 338 | 5 |

| 1790-5M | 5x1790Lp | 1790 | 358 | 5 |

| 1800-5M | 5x1800Lp | 1800 | 360 | 5 |

| 1895-5M | 5x1895Lp | 1895 | 379 | 5 |

| 2000-5M | 5x2000Lp | 2000 | 400 | 5 |

Standard widths: 20mm, 30mm, 50mm and 85mm

| Reference | Size | Length Lp (mm) | No. of Teeth | Tooth Pitch (mm) |

|---|---|---|---|---|

| 384-8M | 8x384Lp | 384 | 48 | 8 |

| 480-8M | 8x480Lp | 480 | 60 | 8 |

| 544-8M | 8x544Lp | 544 | 68 | 8 |

| 560-8M | 8x560Lp | 560 | 70 | 8 |

| 600-8M | 8x600Lp | 600 | 75 | 8 |

| 632-8M | 8x632Lp | 632 | 79 | 8 |

| 640-8M | 8x640Lp | 640 | 80 | 8 |

| 656-8M | 8x656Lp | 656 | 82 | 8 |

| 680-8M | 8x680Lp | 680 | 85 | 8 |

| 720-8M | 8x720Lp | 720 | 90 | 8 |

| 760-8M | 8x760Lp | 760 | 95 | 8 |

| 800-8M | 8x800Lp | 800 | 100 | 8 |

| 840-8M | 8x840Lp | 840 | 105 | 8 |

| 880-8M | 8x880Lp | 880 | 110 | 8 |

| 896-8M | 8x896Lp | 896 | 112 | 8 |

| 920-8M | 8x920Lp | 920 | 115 | 8 |

| 960-8M | 8x960Lp | 960 | 120 | 8 |

| 1000-8M | 8x1000Lp | 1000 | 125 | 8 |

| 1040-8M | 8x1040Lp | 1040 | 130 | 8 |

| 1080-8M | 8x1080Lp | 1080 | 135 | 8 |

| 1120-8M | 8x1120Lp | 1120 | 140 | 8 |

| 1160-8M | 8x1160Lp | 1160 | 145 | 8 |

| 1200-8M | 8x1200Lp | 1200 | 150 | 8 |

| 1280-8M | 8x1280Lp | 1280 | 160 | 8 |

| 1328-8M | 8x1328Lp | 1328 | 166 | 8 |

| 1400-8M | 8x1400Lp | 1400 | 175 | 8 |

| 1440-8M | 8x1440Lp | 1440 | 180 | 8 |

| 1552-8M | 8x1552Lp | 1552 | 194 | 8 |

| 1600-8M | 8x1600Lp | 1600 | 200 | 8 |

| 1760-8M | 8x1760Lp | 1760 | 220 | 8 |

| 1800-8M | 8x1800Lp | 1800 | 225 | 8 |

| 2000-8M | 8x2000Lp | 2000 | 250 | 8 |

| 2400-8M | 8x2400Lp | 2400 | 300 | 8 |

| 2600-8M | 8x2600Lp | 2600 | 325 | 8 |

| 2800-8M | 8x2800Lp | 2800 | 350 | 8 |

| 3280-8M | 8x3280Lp | 3280 | 410 | 8 |

| 3600-8M | 8x3600Lp | 3600 | 450 | 8 |

Standard widths: 40mm, 55mm, 85mm, 115mm and 170mm

| Reference | Size | Length Lp (mm) | No. of Teeth | Tooth Pitch (mm) |

|---|---|---|---|---|

| 966-14M | 14x966Lp | 966 | 69 | 14 |

| 1190-14M | 14x1190Lp | 1190 | 85 | 14 |

| 1260-14M | 14x1260Lp | 1260 | 90 | 14 |

| 1344-14M | 14x1344Lp | 1344 | 96 | 14 |

| 1400-14M | 14x1400Lp | 1400 | 100 | 14 |

| 1610-14M | 14x1610Lp | 1610 | 115 | 14 |

| 1778-14M | 14x1778Lp | 1778 | 127 | 14 |

| 1890-14M | 14x1890Lp | 1890 | 135 | 14 |

| 1904-14M | 14x1904Lp | 1904 | 136 | 14 |

| 2100-14M | 14x2100Lp | 2100 | 150 | 14 |

| 2310-14M | 14x2310Lp | 2310 | 165 | 14 |

| 2450-14M | 14x2450Lp | 2450 | 175 | 14 |

| 2590-14M | 14x2590Lp | 2590 | 185 | 14 |

| 2800-14M | 14x2800Lp | 2800 | 200 | 14 |

| 3150-14M | 14x3150Lp | 3150 | 225 | 14 |

| 3360-14M | 14x3360Lp | 3360 | 240 | 14 |

| 3500-14M | 14x3500Lp | 3500 | 250 | 14 |

| 3850-14M | 14x3850Lp | 3850 | 275 | 14 |

| 4326-14M | 14x4326Lp | 4326 | 309 | 14 |

| 4578-14M | 14x4578Lp | 4578 | 327 | 14 |