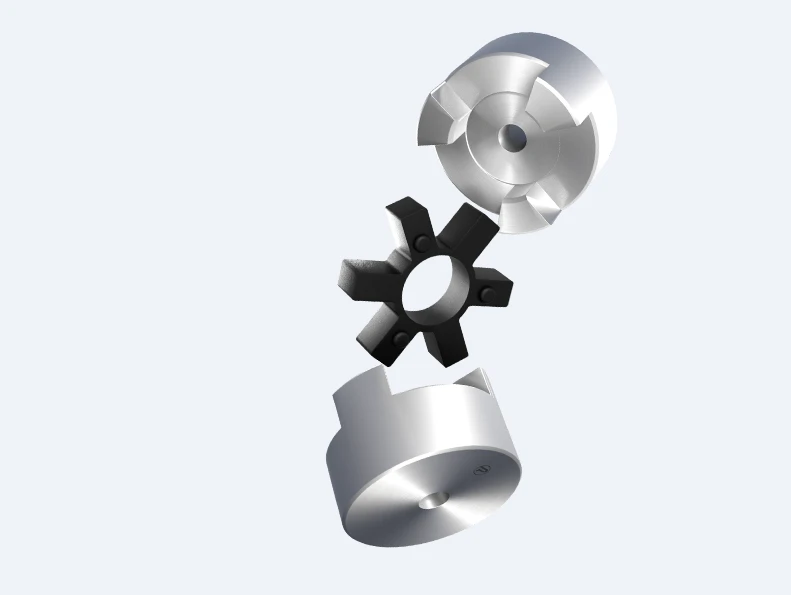

Straight jaw coupling

Maintain stable and efficient mechanical performance.

Renowned for accommodating shaft misalignments, absorbing shocks, and minimising vibrations, straight jaw couplings contribute to consistent and efficient mechanical operation. Their durability makes them ideal for a wide range of industrial applications.

Straight jaw couplings are an affordable and reliable option for general power transmission applications. They help cushion moderate shock loads and minimise low-level vibrations. Designed for simple installation and requiring reduced ongoing maintenance, these couplings are available with flexible elements made from nitrile allowing customisation based on torque needs and spatial limitations.

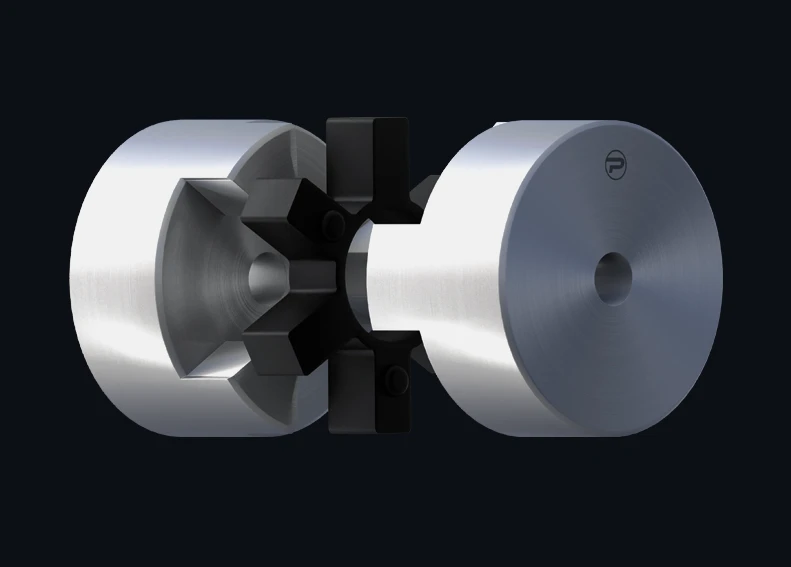

ABSORB IMPACTS & VIBRATIONS

Flexible elastomer insert dampens shock loads, transferring loads and absorbing impacts and vibrations.

TORSIONAL RESILIENCE

Manage dynamic loads and mild misalignments with moderate torsional flexibility, protecting surrounding equipment.

REDUCED MAINTENANCE

Simple wear-resistant design requires no lubrication or maintenance.

Misalignment

Handles angular misalignment up to 1° and parallel misalignment up to 0.38mm.

Reduced maintenance

Due to the fail-safe design, elements fail while maintaining the integrity of the hubs and surrounding equipment, and with no lubrication required, maintenance is reduced.

Large temperature range

Operates effectively in temperatures ranging from -40°c to +140°c, suitable for diverse environments.

Element design

Nitrile wrap elements available for ease of installation.

DIN/ISO

DIN 740-1

Technical data

| Size | Type | A | B | C | D | Stock bore (mm) | Max bore (mm) | Weight (kg) | Max RPM | Torque (Nm) |

|---|---|---|---|---|---|---|---|---|---|---|

| 070 | 1 | 34.53 | 50.801 | 12.7 | 19.05 | 6.35 | 19.05 | 0.27 | 14000 | 5.77 |

| 075 | 1 | 44.45 | 53.98 | 12.7 | 20.64 | 6.35 | 22.23 | 0.45 | 11000 | 11.9 |

| 090 | 1 | 53.58 | 53.98 | 12.7 | 20.64 | 6.35 | 25.4 | 0.67 | 9000 | 19.2 |

| 095 | 1 | 53.58 | 63.5 | 12.7 | 25.4 | 11.11 | 28.58 | 0.79 | 9000 | 25.8 |

| 100 | 1 | 64.29 | 88.9 | 19.05 | 34.93 | 11.11 | 34.93 | 1.55 | 7000 | 55.4 |

| 110 | 1 | 84.14 | 107.95 | 22.23 | 42.86 | 15.88 | 41.28 | 2.93 | 5000 | 105 |

| 150 | 1 | 95.25 | 114.3 | 25.4 | 44.45 | 15.8 | 47.63 | 4.06 | 5000 | 150 |

| 190 | 2 | 101.6 | 123.83 | 25.4 | 49.21 | 19.05 | 53.98 | 4.01 | 5000 | 200 |

| 225 | 2 | 107.95 | 136.53 | 25.4 | 55.56 | 19.052 | 60.33 | 5.57 | 4200 | 280 |